Wie sich Farben auf die MOQ auswirken: Eine praktische Analyse von Handwerk und Verfahren

In vielen Branchen, vor allem in der Textilproduktion und -konfektionierung, gibt es häufig die Anforderung, eine Minimum Order Quantity (MOQ). This requirement often leads to questions from clients when placing an order: Why do some products require a minimum quantity? Why does my supplier say it’s impossible to produce 20 pieces in one color?

To address this, I’ve written a series of articles titled Why Customized Partnerships Have a Minimum Order Quantity. This article analyzes why colors affect MOQ from the perspective of craftsmanship and production processes. You can visit Kleinserien-Anpassung for more knowledge.

Digitaldruck Vs MOQ

Taking digital printing as an example, during the operation of a printing machine, especially at the beginning, there is always a small amount of waste material due to the machine not running smoothly. The causes of this situation may include:

- Cold starts causing friction and temperature differences, leading to instability.

- Ink settling in nozzles, causing unstable flow or clogs.

- Calibration and adjustment waste before proper printing begins.

For these reasons, when customers request a small quantity for each color, especially with multiple colors, the initial waste becomes significant. The time and resources spent stabilizing the machine for each color contribute to higher operational costs, making it impractical for suppliers to fulfill such small custom printing orders at a reasonable price.

Färben VS MOQ

If we use dyeing processes instead of printing, the situation doesn’t improve significantly. Dyeing processes typically require large dye vats. In small-batch production, the time and cost for equipment adjustments, dye mixing, and cleaning still exist. These adjustments and startup waste (like dye liquor consumption) are noticeable in small batches, significantly increasing the unit cost.

Manufacturers often set an MOQ to ensure the production process is economically viable, spreading the costs of adjustment and wastage across a larger number of units.

Produktionsprozess VS MOQ

One client asked: “Why can’t you make 10 pieces for me at the wholesale price? Isn’t it just printing 10 copies?” This misunderstanding comes from not knowing the complexity of the manufacturing process.

A mulberry silk scarf manufacturing process involves 11 stages, including fabric inspection, sizing, digital printing, washing, high-temperature color fixing, softening, drying, quality inspection, and hand-rolling. For quantities under 50 pieces per design, the cost increases significantly. Even professional factories cannot reach the limit of 30 pieces at wholesale prices.

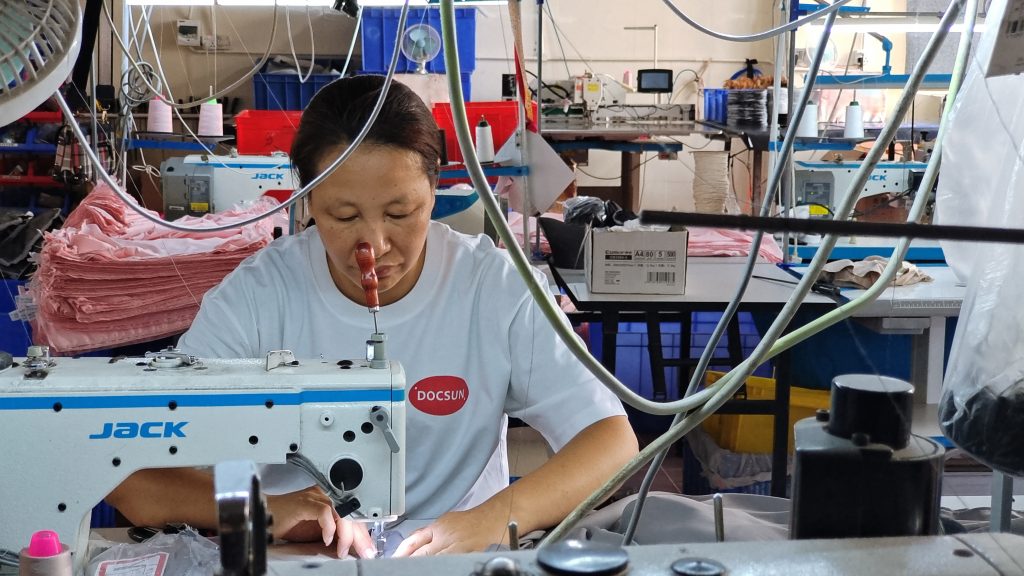

In textile or custom garment production, changing sewing threads or dye consumes time and resources. Adjusting machinery, cleaning equipment, and conducting color tests require additional labor costs, making small batch orders less cost-effective.

Vorschläge und Schlussfolgerungen

Bigger factories are not necessarily better for small orders as they require higher MOQs. It is important to find a supplier whose scale matches your needs. In the early stages, using suppliers’ stock colors ensures a smaller MOQ. For patterned silk scarves, find a trustworthy supplier and heed their advice regarding MOQs.

If you have questions about MOQs or need a quote, please contact us.

Frequently Asked Questions (FAQ)

Why does digital printing have a Minimum Order Quantity (MOQ)?

How does the dyeing process affect MOQ?

What is a good strategy for startups to manage MOQ?

“`